What is Evaporative Cooling?

Have you ever felt cold after taking a bath? If yes, you experienced evaporative cooling. The water droplets evaporate by absorbing heat from your skin. The result? Your skin feels cooler – sometimes even making one shiver!

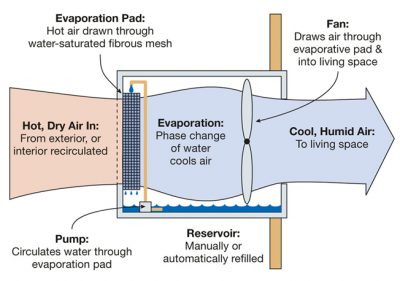

Evaporative cooling systems work on this very principle; water must have heat applied to it to change from a liquid to a vapor. In these systems, a fan draws hot outside air through the water-soaked pads. Adding heat to this water evaporates it. When this evaporated water vapor is combined in the air, the air temperature is reduced. A temperature reduction of as much as 20 degrees can be achieved using this system of cooling.

When air passes over a stream of water, water vapor is added into the air, lowering the air temperature. The energy needed for evaporation is taken from the air and the loss of energy is reflected as a reduction in the air temperature. This phenomenon is called evaporative cooling.

Evaporative cooling is one of the most efficient cooling systems in areas of low humidity; less moisture content facilitates more evaporation, and hence temperature reduction. However, in humid areas, these systems work less efficiently as the high humidity content in the air discourages evaporation, which in turn does not let the air temperature drop. We experience this fact daily as well. After bathing, we feel cooler as soon as we open the bathroom door. This is because the air inside the bathroom has become more humid than the air outside; hence evaporation occurs at a faster rate outside the bathroom.

Two basic types of evaporative coolers:

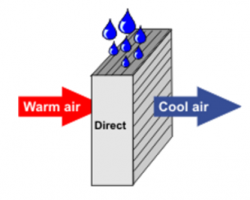

- Direct Evaporative Coolers: This is a traditional cooler that works well in hot & dry climates. Warm outside air is pulled through moist pads where it is cooled by evaporation. The cool air, with added moisture, is then drawn to the space requiring cooling using a blower.

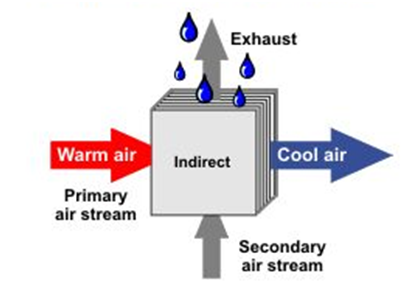

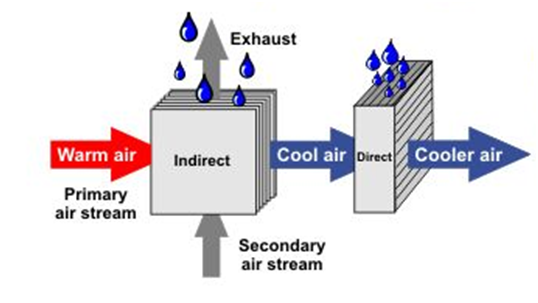

- Indirect Evaporative Coolers: This cooler works on the same principle as direct evaporative cooling – lowering air temperature by causing water to evaporate. The main difference with an indirect system is that a sensible heat exchanger is used as a medium to cool the air supplied to the living space. The evaporative cooling cycle occurs in the heat exchanger.

- Same principle as perspiration on the human body.

- As air passes over the skin evaporation takes place and a cooling effect is felt.

- Evaporative air coolers use filter pads as the cooling outer skin.

- A fan draws air through the water-soaked pads, evaporating the water and cooling the air that is then blown into the house.

- A temperature reduction of as much as 20 degrees can be achieved.

- Evaporative cooling is most efficient in areas of low humidity.

- Achieved by natural evaporation of water.

- Evaporation of water requires 540 kcal of heat per kg. Conversely, the same quantum of cooling is generated when water evaporates.

- Dry bulb temperature of air drops as a consequence of the evaporative effect.

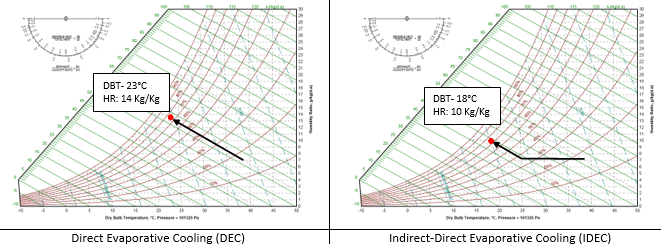

- On the psychometric graph air moves towards water saturation and the circulating water cools down till it reaches its saturation temperature or wet-bulb temperature.

Evaporative Cooling Working Principle

Science Principle

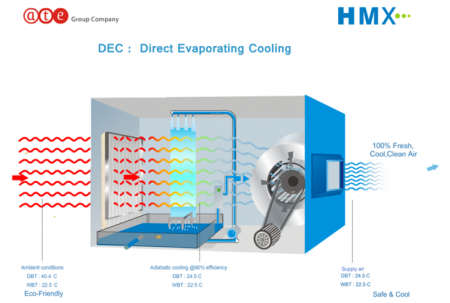

Direct Evaporative Cooling

- The evaporative cooling addresses sensible cooling requirement of ambient air Latent cooling requirement remains unaffected

- No reduction in ‘total heat content’ or enthalpy of air. Hence cooling effectiveness represented by the reduction in dry-bulb temperature and not ‘TR’

- Requires low relative humidity (i.e. the ability for air to absorb significant additional moisture) to yield effective cooling

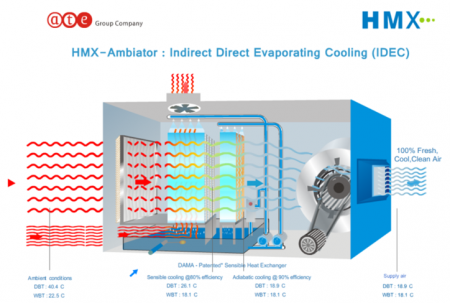

Indirect-Direct Evaporative Cooling

- Cools air without adding humidity, Dry-Bulb and Wet-Bulb temperature of air drops as a consequence of the evaporative and heat-exchange effect

- On the psychometric graph air moves horizontally along the constant humidity line (but increasing RH % – since at the cooler DBT it can hold less additional moisture) towards saturation and the circulating water cools down till it reaches it’s saturation temperature or wet-bulb temperature

- ‘Cooling Effect’ generated in one path-way is transferred to a physically separated stream of air (which will eventually be supplied to the occupied space) through a heat-exchange process across ‘thin walls’

- Indirect Evaporative Cooling addresses the sensible cooling requirement of ambient air

- The latent cooling requirement remains unaffected

- Leads to the reduction in ‘total heat content’ or enthalpy of air

- Can operate in moderately humid air conditions as well (i.e. more robust in its climatic range relative to Direct Evaporative Coolers)

- Combined Direct and Indirect Evaporative Cooling in sequence (2 stage Evaporation) provides cooler air than is possible through each process separately.

Performance comparison between DEC and IDEC

Engineering Principles

Direct Evaporative Cooler

- A fan moves the supply air past a wetted media, adding moisture to the supply air stream to accomplish the evaporative cooling effect

- Cellulose Pads impregnated and treated to resist biological and mechanical degradation

- Cross fluted design enhances surface area to hold water on which air flows and causes air to change directions to ensure all air touches wetted media before leaving the area

- Combined Direct and Indirect Evaporative Cooling in sequence (2 stage Evaporation) provides cooler air than is possible through each process separately.

Engineering Principle - Direct Evaporative Cooling

Indirect/Direct Evaporative Cooler

Indirect Evaporative cooling

- Secondary air stream passes through the wetted media and is cooled down by the water

- Primary air stream loses its heat while passing through a heat exchanger containing chilled secondary air stream. However, there is no moisture added to the primary air stream.

- This cooled air is now circulated in the room by blower

Engineering Principle - Indirect Evaporative Cooling

Indirect-Direct Evaporative Cooling

- The first stage is indirect evaporative cooling where primary air loses its heat to cool and humid secondary air stream through a heat exchanger.

- In the second stage, additional cooling happens when this cooled primary air directly passes through a wetted media. The evaporation effect further reduces the air temperature leaving the system

- The amount of moisture gained by the primary air in this system is much lower than direct evaporative cooling.

Figure 4: Engineering Principle - Indirect-Direct Evaporative Cooling

Operation Mechanism

Direct Evaporative Cooler

- Outside air is pulled inside via fan

- Water is pumped up to pass through wetted media

- Air when passes through wet media, loses heat to water and absorbs the moisture. At this stage, Dry Bulb Temperature of the air reduces but the Wet Bulb Temperature remains constant (as cooling happens through the phase change of water)

- Cold humid air is circulated inside the room by a blower

Direct Evaporating Cooler

Indirect Direct Evaporative Cooler

- A fan pulls a secondary air stream which passes through the sensible heat exchanger, thereby absorbs moisture and loses its heat

- Another fan pulls primary air stream, which passes through a heat exchanger with secondary air stream inside. Heat is transferred from primary to secondary air without the addition of moisture.

- At this stage, both the Dry Bulb and Wet Bulb temperature of the primary air reduces

- In the next stage, the primary air stream passes directly through the wetted media, where it absorbs moisture and further loses its heat. Since the temperature of this air stream is lower than the secondary air stream, the amount of moisture absorbed is also lower.

- With the help of a blower, cooled primary air is circulated inside the room

Indirect Direct Evaporating Cooling (IDEC)

Direct Evaporative Cooling

- Industries – Provides comfort to staff from hot indoor climate, thus leading to a reduction in errors and increased productivity

- Commercial – Customized sizes to fit in any air handling unit, thus improving the working environment of the businesses.

- Residential – Customized sizes to fit specific residential requirements

- Poultry Industry – Lower air temperatures, reduces heat-stress related problems

- Horticulture Industry – Ensures the balance of temperature in greenhouses

Indirect Direct Evaporative Cooling

- Factory sheds

- Warehouse

- Laboratories

- Office complex

- Entrance lobbies

- Cafeterias

- Malls

- Lecture / training rooms

- Function halls

- Kitchen/Laundry

- Extremely low power consumption relative to conventional ACs: EER of EAC ~ 20 in Hot & Dry Regions vs. EER of 2.8 for 3-Star AC

- Use of natural refrigerant for cooling: Water

- Much lower capital cost and life-cycle operational cost, energy consumption, and GHG emissions

- Better building occupants’ health condition due to more fresh air intake and circulation

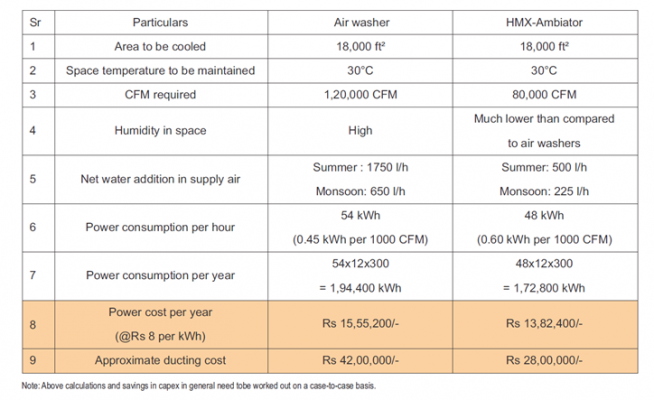

Suzlon One Earth

ICC Devi Gaurav Tech Park, Pimpri-Chinchwad, Maharashtra

- Lobby Atrium of 18,000 ft2 is cooled only with Indirect-Direct Evaporative Cooling; no use of air conditioning

- The atrium door needs to be open at all times to enable free movement of people

- Space temp. < 300 ℃

- Water addition max 500 liters/hr

- Peak ventilation air required – 136,000 m3/ hr

- Peak power requirement to cool the space is 48 kW/hr

- Installed with 4 X 34,000 CMH capacity cooling system

Summertime temperature less than 300 C with an ambient temperature of 400 C

Comparison between air washer and IDEC

Atrium ventilation at ICC Tower, Pune

View Evaporative Cooling resources for Architects and for Engineers.

| Manufacturer | Product | Contact |

| A.T.E. ENTERPRISES PRIVATE LIMITED (BUSINESS UNIT: HMX) | HMX-ATE (Ambiator), HMX-IEC, IDECool 6 V 1.1, IDECool 15 and IDECool 25 | Plot no 113 & 114, Phase III, Peenya Industrial Area, Bengaluru - 560 058, India Email: ambiator@hmx.co.in, Phone: +91 80 - 2372 1065 / 2372 2325 |

| Arka Clean Technologies | Evaporative Cooling Equipment | Dhayri, Pune +91 98230 81757 / +91 87888 25644 |

| Boom Age Engineering Solutions Pvt. Ltd. | Evaporative Air Cooling Systems | Office No. 1,2 & 3 Arvind Apartment, Opp. Mantri Hospital, 94 Erandwane, Near Mhatre Bridge, Pune - 411004, Maharashtra, India, Phone :09901341338 |

| Roots Air Systems | Roots Air Hybrid Units, Roots Air Compact Energy Efficient Evaporative Cooling Units | B - 9, Sector 59,Noida - 201301 (U.P.) Phone: 0120 - 2586497 / 98 |

| Roots Cooling Systems | Indirect / Direct Evaporative Cooling Units, Single / Double-skin Evaporative Cooling Units | B- 53, Hosiery Complex, Phase – II, Noida, Uttar Pradesh, India - 201305 : Phone: + 91-120-4036100, Email: rcs@erdrcs.com |

| TORO Cooling Sys Pvt Ltd (Ambiator+) | Toro IDEC Ambiator+ Two Stage Evaporative Cooling | Gurudwara Rd, off GT Karnal Slip Road, New Delhi – 110036, India, Phone: +91 93159 54500, 93159 28400, Email: sales@toro.net.in |