Synthetic and Natural Refrigerants for AC

The entire refrigerant family can be first differentiated as fluorinated versus non-fluorinated gases. The fluorinated refrigerants such as chlorofluorocarbon (CFC), hydrochloric fluorocarbons (HCFC), perfluorocarbons (PFC), hydrofluoro ethylene (HFE) and hydrofluorocarbons (HFC) have one common element, fluorine which is a chemical substance represented by the symbol ‘F’. On the other hand, the non-fluorinated refrigerants lack the element fluorine and they are referred to as natural refrigerants.

Source: Hydrocarbon Refrigerants For Room Air Conditioners, Daniel Colbourne, for GIZ Proklima, March 2011

Environmental issues of conventional refrigerants

The conventional refrigerants such as R 410A, R22, R134A, R32 have a high global warming potential (GWP) as compared to carbon dioxide refrigerant R744. Example to interpret GWP and its impact is, for instance, the most commonly used refrigerant in India for air conditioners is R22 refrigerant, a hydrochlorofluorocarbon having GWP of 1810 which means that one molecule of that gas when it leaks out into the atmosphere has 1,800 and 10 times the impact of one molecule of carbon dioxide leaking into the atmosphere, therefore, these are called super greenhouse gases.

It is important to reduce the environmental and climate change impacts of air conditioners by moving from the high global warming potential gases to the ones that have much lower global warming potentials. R32 refrigerant is being marketed in India as a low global warming potential gas, however, R32 is still fluorinated and has a relatively high global warming potential of 675.

With the advanced technologies, the most sustainable and low global warming potential gases available to us right now are R290, R1270, R744, R717.

| Refrigerants | Type | GWP (100 Year, AR 2007) |

| R410A – R32/R125 – 50:50 | HFC | 2088 |

| R22 – Chloro Difloro Methane | HCFC | 1810 |

| R134A – Tetrafloro Ethane | HFC | 1430 |

| R32 – Methylene Fluoride | HFC | 675 |

| R290 – Propane | HC, ‘Natural’ | 3.3 |

| R1270 – Propylene | HC, ‘Natural’ | 1.8 |

| R744 – Carbon Dioxide | ‘Natural’ | 1 |

| R717 – Ammonia | ‘Natural’ | 0 |

AC Refrigerant Progression

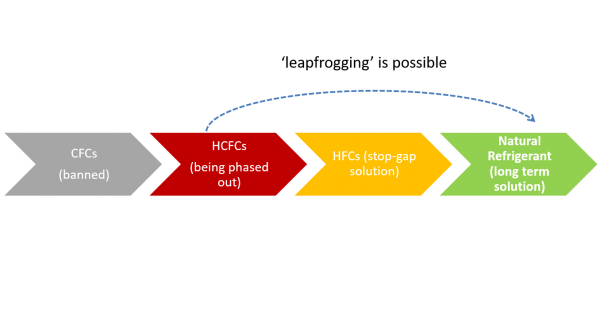

In the early 90s, the world dealt with banning the ozone layer issue as the layer was getting depleted because of the leakage of chlorofluorocarbons (CFC) from cooling devices. The CFCs have been substituted by hydrochlorofluorocarbons as a solution to the ozone layer issue, however, HCFC has high global warming potential, thereby, leading to other environmental issues. The conventional AC industry is slowly phasing out the high GWP refrigerants instead of completely moving to natural solutions.

Leaf – frogging model of Natural Refrigerant for India

The leap-frogging of the current refrigerant to natural refrigerant is relevant for India because India is not a saturated air conditioning market. Homes in India have installed about 41 million room ACs whereas the current population is about 1.3 billion. The process of lead – frogging can make sure that the next 1 billion people who consume air conditioners having sustainable refrigerant.

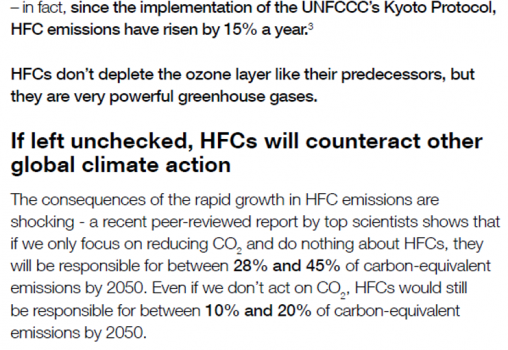

Increased GHG Emissions

The statement highlighted the need for natural refrigerants that don’t have fluorine in their chemical mix. The detrimental impacts of increasing use of HFC can nullify the affords made by reducing carbon dioxide and other greenhouses by reducing the number of cars we use, the number of fertilizers we put on our fields, or the amount of energy consumption.

HFC could be responsible for 28 to 45 percent of the world’s carbon footprint by the year 2050 so an issue which is almost non-existent in our mainstream environmental discourse. However, in India, leapfrogging is possible by adopting natural refrigerants right away.

Why use Natural Refrigerants?

- Natural refrigerants deliver on the Montreal and Kyoto Protocols.

- Natural refrigerants have no or very low Global Warming Potential (GWP)

- Zero Ozone Depleting Potential (ODP) – Montreal Protocol

- Reduction of CO2-equivalent emissions – Kyoto Protocol

R 290 is the most dominant alternative refrigerant right now in case of India. R 290 can be understood by looking at four dimensions.

- Environmental

- Safety

- Efficiency

- Price

R290 Analysis : Environmental

To understand the environmental benefits and implications of R 290, the chart presents the most conventional current refrigerants used in India. Hydrochlorofluorocarbon (HCFC22) or R22 and HFC410A are currently being sold in India as a green refrigerant due to low and zero ozone depletion potential respectively, however, they have high global warming potential. Hydrofluoro Olefins are also fluorocarbon (HFC410A) has also been portrayed as an alternative to the conventional refrigerants.

R290 is a great alternative refrigerant, however, the refrigerant is highly flammable. By minimizing the amount of leakage of this refrigerant into the spaces where people are occupying may provide as a replacement to the mainstream refrigerants.

| Refrigerants | ODP | GWP | Flammability | Refrigerant Characteristics | |

| Current Refrigerants in Energing countries | HCFC22 | 0.055 | 1810 | Non - flammable | Production to be completely phased out in developed countries by 2020 |

| Current Refrigerants in Developed countries | HFC410A | 0 | 2,088 | Non-flammable | Slowly replaced by propane in developed countries |

| Next generation Refrigerants | HFO1234yf/ze | 4-6 | Slightly flammable | No impact on ozone and low GWP.Safety and Price issue | |

| Next generation Refrigerants | HFC32 | 0 | 675 | Slightly flammable | No impact on ozone and one of the lowest GWP among HFCs. Flammable |

| Next generation Refrigerants | CO2 | 0 | 1 | Non-flammable | No impact on ozone and low GWP. Low efficiency when used for AC |

| Next generation Refrigerants | Propane (R290) | 0 | 3 | Highly Flammable | No impact on ozone and low GWP. An efficient refrigerant, but highly flammable and susceptible to explosion |

R290 Analysis: Safety

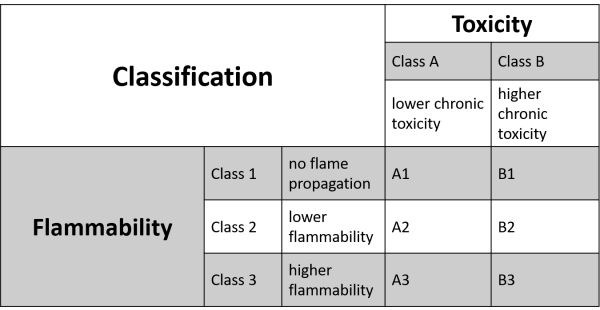

The environmental flammability and toxicity impacts are classified for a refrigerant in an air-conditioner. Toxicity is classified as Class A and Class B and flammability as Class 1, Class 2 and Class 3. Refrigerants having low toxicity and low flammability are selected across the world, however, the classification does not mention the threat posed by the high GWP of these refrigerants.

Refrigerant Safety / Toxicity Classification

Flammable gases such as CNG AND LPG are used as a fuel in car and kitchen. One point here to demystify is we don’t call our cars as flammable, we call the fuel flammable since engineers and car designers have applied engineering principles which make the car safe for people to use, similarly, liquid petroleum gas is commonly used in our kitchens in India.

Flammability Concerns Related to R290:

- It belongs to safety group A3 and is highly flammable and non-toxic.

- Lower Explosive Limit – 2.1 % vol/vol, Upper Explosive Limit – 9.5 % vol/vol.

- Color Less and Odor less Gas

- Flash Point is below the atmospheric temperature and exposure to the atmosphere in combination with spark/flame/hot surface may cause fire immediately

- Readily forms an explosive air-vapor mixture at ambient temperatures.

- Vapour is heavier than air and may travel to remote sources of ignition (e.g. along drainage systems, into basements etc).

R290 Analysis : Efficiency

Efficiency Perspective: Natural refrigerants are energy efficient

| Parameters | R22 | R290 | R1270 | R410A | R32 |

| Volumetric Refrigerating Effect (KJ/m3) | 4359 | 3716 | 4643 | 6275 | 6824 |

| Relative to R22 (%) | 0 | -15 | 2 | 44 | 57 |

| Discharge Temperature (Deg C) | 95 | 77 | 83 | 92 | 111 |

| Relative to R22 (Deg C) | 0 | -18 | -13 | -3 | 15 |

| Coefficient of Performance (KW/KW) | 4.23 | 4.28 | 4.21 | 3.96 | 3.98 |

| Relative to R22 (%) | 0 | 1 | -1 | -6 | -6 |

Efficiency Related Data of R744 (Carbon Dioxide) and R717 (Ammonia) is not available

R290 Analysis : Price

Economic (Price) Perspective: Natural Refrigerants Are Inexpensive

- Universally Available

- No Patent

- Direct Material cost (Refrigerant Cost) of HC-AC and Conventional ACs are not significant for comparison

- Life Cycle Analysis of HC-AC with Conventional AC is presented in slides no. 19 – 28 Slides

R290 Split ACs

HC-AC vs. Conventional Split/Window ACs

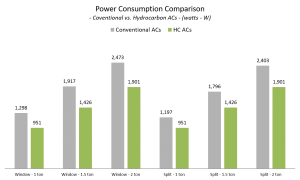

Power Consumption Comparison

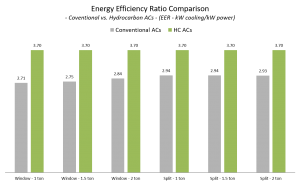

Energy Efficiency Ratio Comparison

Fairconditioning has conducted the life cycle costing study of 3 – star split AC and Godrej EON AC having R290 refrigerant. The result found that R290 is economically and environmentally beneficial. In India, one 3 – star Split AC runs for approximately 1,000 hours a year, which is close to about three hours a day for the full year or slightly longer periods on summer days.

The average cost to run a 3-star split AC over 10 years is approximately Rs. 1.6 lakh and the starting cost is about Rs. 28000. The initial cost of Godrej Eon AC, which has R290 as a refrigerant, is Rs. 37,000 rupees, however, the lifetime cost is much less and spend less energy. Therefore, switching to R290 will give economical and environmental long term benefits. For example, if one home having conventional AC is replaced by AC like Godrej EON, we will be able to power 36 ceiling fans, save about 10,000 rupees annually, 120 lightbulbs could be lit in other people’s homes and it would be the equivalent of three cars being taken off the road in terms of reduced pollution and global warming impacts, therefore, these are this is a win-win-win technology environmentally and ecologically.

Comparison Study of 3-star Split AC and Godrej Eon

R290 Central AC Systems

Centralized air conditioning systems can use R290 refrigerant, by having chiller unit outside the building.The chillers are systems which have a cooling system which cools a circuit of water and the water is circulated through the entire building therefore the safety rules can be different because there are no humans in the part where the refrigerant is enclosed it’s only tubes of water and the safety considerations for water are very different from those of human occupation so these systems are able to have two cooling loops – one is the refrigerant cooling the water and then the cooling the cooled water going into the building and in this way they can have systems as large as two or three hundred tons.

England the Westminster Abbey church house has a cooling system which has a capacity of about 150 tonnes of cooling or 600 kilowatts of cooling and it uses R290 and it uses chiller loops so it’s completely safe to use in a large-scale chiller system.

R290 Chiller installed at Church House, Westminster Abbey

Safety Considerations for R290

- Key safety criteria – AC Circuit Charge Level

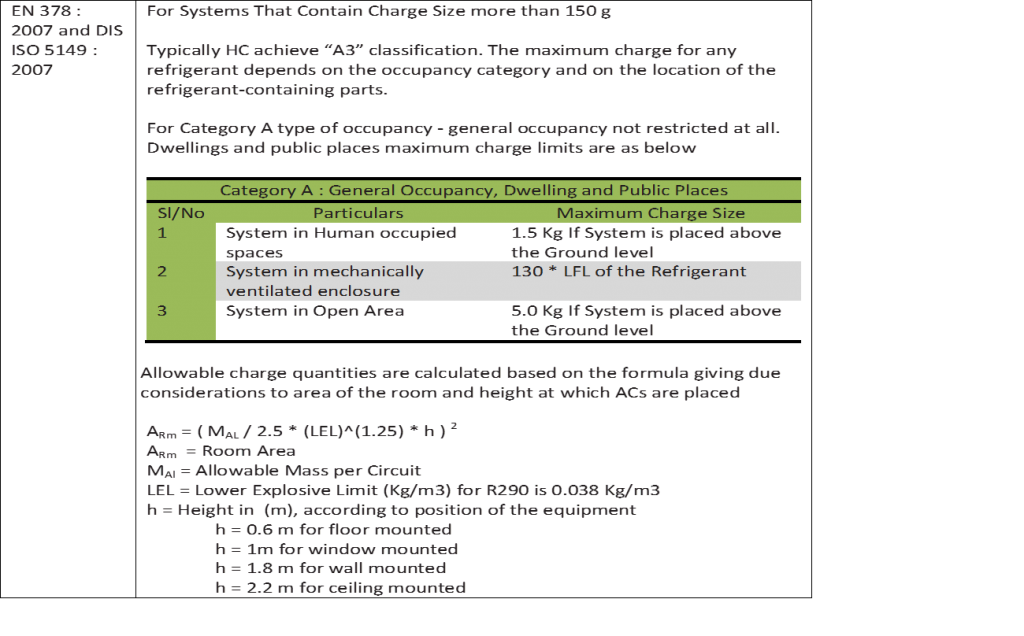

The mathematical relationship that helps to use the value of lower explosive limit to arrive at a certain maximum allowable refrigerant in one AC.

The equation is used by the ISO standard and the European standards to define the maximum allowable refrigerant in an AC. The maximum allowable charge is a function of the room area, lower explosive limit, and the room height.

- R290 Refrigerant in ACs by category ‘A‘ people

All general safety considerations like electrical operations, Installation site etc has to be followed as followed during HCFC/HFC ACs installation / Repair / Modification / maintenance / disposal. Safety can be addressed by using 5 broad classifications:

- During Construction / Manufacturing

- During Operation

- During Maintenance / Recharging

- During Disposal

- Additional Safety Considerations

Safety Considerations During Construction / Manufacturing

- All tubing joints should be brazed properly, should not be installed in such a way that bends or joints are stressed and should be cross checked.

- Since R290 is denser than air, it will collect at the bottom of the enclosure in case of leakage therefore the base is constructed as a leak-proof pan so that any releases will be held within the enclosure.

- At least one gas sensor is positioned inside air-tight enclosure, where upon exceeding a pre-set concentration the gas sensor isolates the electricity supply and also give a warning signal.

- Even if the total HC-290 leaked make sure that the concentration is below the explosive density of R290 (43.6 to 175 g/m3).

- The electrical components like capacitor, thermostat switch has to be sealed.

- No valves and detachable joints must be located in areas accessible to the general public. Ensured that the refrigerant charge of the of the system do not exceed the charge size limits.

- All refrigerant-containing and other critical parts of the equipment must be protected from mechanical damage.

Safety Considerations During Operation

- Smoking has to be prohibited.

- The equipment should be positioned so that there is always good free ventilation around all sides of the equipment, and it will not be inhibited by any permanent or temporary blockages.

- The area should be free of combustible materials.

- The equipment housing should be designed to prevent or inhibit interference from others, possibly by Locks etc.

- Consideration should be given to the positioning of the equipment with regards to areas where people may congregate or gather.

- Do not install system in Humid places and do not clean the system with water.

- Air Conditioner must be kept away from fire, spark with energy > 20mJ /hot surfaces > 450 deg C to prevent the ignition of R290 (Auto ignition temp 540 deg C).

- If anything irregular occurs like burnt parts, smell, loud noise then disconnect the system immediately and isolate the system from electric supply.

Safety Considerations During Maintenance & Re-Charging

- Regular maintenance and system checks have to be made.

- Any technician working on a system must be properly trained and certified with the appropriate qualifications.

- Before servicing the unit, the surrounding area where the work will be done must be clear of safety hazards to ensure safe working.

- Nevertheless, it is required to carry out a risk assessment in order to minimize the risk of ignition of R-290.

- It is recommended to isolate the working environment in order to keep out any unauthorized personnel.

- It is prohibited to store any combustible goods within the working environment.

- Within two (2) meters radius, ignition sources are not allowed in the working area.

- Fire extinguisher (dry powder) must be easily accessible at any time.

Safety Considerations During Refrigerant Recovery

- The recovery cylinder must be permitted for the use of R-290 (especially regarding the pressure and the compatibility of the connectors and the valves).

- The recovery machine must be suitable for operation with R-290. Importantly, the recovery machine must not itself be an ignition source.

- The filling of the recovery cylinder should be monitored closely by controlling the weights. The cylinder should not be filled more than 80% of its complete volume by liquid refrigerant

- Pressure and mass of the cylinder must be controlled.

- After recovery type of recovered refrigerant must be marked. Recovery machine has to be operated until the pressure reduces to 0.3 bar. R290 is soluble in oil. This may lead to rising in pressure as refrigerant vaporizes from oil.

- It may be necessary to operate the recovery machine for a second or even a third time.

- Remaining amounts of HC absorbed by the oil can be extracted from the system using a vacuum pump in combination with an exhaust vent hose.

- Small amounts of R-290 can be vented in a safe manner to the environment.

- After the systems‘ pump out, the system should be flushed with Oxygen Free Dry Nitrogen (OFDN) in order to ensure no flammable gas is inside the system.

Safety Considerations During Leak Repair

- Removing the refrigerant from the system in order to avoid an uncontrolled discharge.

- Examine the leak source, determining the reason for the leak and carry out the proper course of action.

- Repair properly (NO “temporary repairing”)

- Based on the results of the systems’ examination, suitable measures need to be identified in order to avoid a recurrent appearance of the leak.

- Before embarking on the repair, ensure that the refrigerant has been removed and the system flushed with OFDN, especially if brazing is to take place.

- After each intervention into a refrigeration system (repairing leaks, replacing components, brazing) the system must be subject to a leak test and following strength test of the system.

Safety Considerations During Disposal

- Recovering of the refrigerant must be done by a trained technician.

- During recovery ensure that there is no Spark / Flame / Hot Surface around the system.

- Recovery of the refrigerant must be done at the end of the system life.

- Recovery must be done in a ventilated environment. If at all leak occurs the concentration of R290 gets reduced.

Other Safety Considerations

- R290 is a Class 1 type of flammable material must be enclosed in strong enclosure.

- Enclosure should be strong enough to sustain internal explosion.

- The walls must be thick enough to withstand internal strain during explosion.

- The equipment must provide a way for burning gases to escape.

- Only after the gases have been cooled off and their flames are quenched.

- This will avoid the damage to the external surrounding.

- The escape route for gases is provided through several flame paths of very less tolerance.

- Importance to protect flame paths during installation, handling, maintenance, shipping etc. Even a slight damage to the flame paths can permit gases to escape and ignite the surrounding atmosphere.

Low environment impact

- Natural refrigerants have zero ODP and minimal GWP. In comparison, commonly used HCFCs and HFCs have a GWP varying from hundreds to thousands.

High Performance

- They have excellent thermodynamic properties.

Cost competitiveness

- Use of natural refrigerants generally leads to lower operating costs due to less leakage, lower maintenance requirements and better energy efficiency.

Compatibility

- Natural refrigerants work well with commonly used oil and fluids.

| Manufacturer | Product | Contact |

| Godrej & Boyce Manufacturing Company Limited | Godrej Eon Air Conditioner | Pirojshanagar, Vikhroli, Mumbai-400079, India. Phone: +91-22-6796 5656 / 5959 Email: info@godrej.com |

RELATED SUSTAINABLE COOLING TECHNOLOGIES

Radiant Cooling

Structure Cooling

Evaporative Cooling