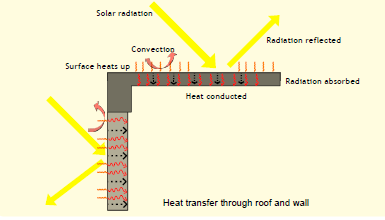

In a hot country like India, the external surfaces of the building envelope – the roof and walls – get heated up at temperatures higher than the prevailing temperature inside the building. From the building envelope, the heat gets transferred through thermal conduction to the inner surfaces of the roof and walls, creating an unwanted heat source within the occupants’ space. The heat gets distributed inside the building further, through radiation and convection, causing much discomfort to the occupants. Hence, it becomes essential that the occupants’ space has the means to ensure good air circulation, ventilation, space cooling, and so on, usually achieved by energy-driven electrical fans and air-conditioning systems. (BEEP, Thermal Insulation of Buildings for Energy Efficiency).

Heat Transfer Through Roof and Wall

Thermal insulation in the walls and roofs reduces heat transfer between the inside and outside, thus helping to maintain a comfortable indoor temperature. It provides a more comfortable indoor environment, adds sound control, and lowers the electricity bills. Insulation helps keep spaces cool in the summer and warm in the winter. (www.nzeb.in)

The lambda (λ) value, also referred to as thermal conductivity, is a value indication how well a material conducts heat. It indicates the quantity of heat (W), which is conducted through 1 m² wall, in a thickness of 1 m, when the difference in temperature between the opposite surfaces of this wall equals 1 K (or 1 ºC). In practice λ is a numerical value expressed in terms of W/(mK). The lower the λ value, the better the insulation property of the material. Compared to several building materials commonly used in construction, such as brick, having a thermal conductivity of 0.5 to 0.7 W/mK, the thermal conductivity of insulation materials is remarkably low, often less than 0.06 W/mK. (www.rockwool-searox.com)

U-value. The transport of thermal energy through a structure is expressed by a coefficient, U (Thermal transmittance coefficient). It represents the flow of heat (in W) through 1 m² of a structure, when the difference between the two surrounding temperatures is 1 K (or 1 ºC). The thermal transmittance coefficient is expressed in W/(m²K). The lower the coefficient, the better the structure insulates. (www.rockwool-searox.com)

R-value. Thermal resistance, R, is a measure used in construction. The R value is the reciprocal U-value. Increasing the thickness of an insulating layer increases the R-value. (www.rockwool-searox.com)

Other important characteristics of the insulation materials, are moisture resistance, fire resistance, potential for generating toxic smoke, physical strength, and stability over time. (Lechner N., 2008)

Thermal insulation materials usually occupy large volumes, but they are light and seldom take up more than about 2% of the building’s total weight. Many of the most common commercial insulation products are derived from fossil oils. Plant-based materials are, however, now attracting more attention. Many of the commonly used insulation products have quite high embodied energy and associated greenhouse gas emissions.

Insulation Materials

There are a variety of materials to choose from including fibre glass, mineral wool, rock wool, expanded or extruded polystyrene, cellulose, urethane or phenolic foam boards and cotton. They are generally in the form of amorphous wool or rigid sheets, or require in‐situ pouring. Insulation is rated in terms of R‐value. Higher R‐values denote better insulation and translate into more energy savings. (www.nzeb.in)

Glass Wool Insulation. Glass wool is an insulating material made from extremely fine fibres of glass, arranged into a texture similar to wool by using a binder. The process traps many small pockets of air between the glass, which ensures high thermal insulation. Glass wool is normally available in three different forms—blanket (batts and rolls), loose-fill, and rigid boards. It may also be produced as a material that can be sprayed or applied on the surface to be insulated. (BEEP, Thermal Insulation of Buildings for Energy Efficiency)

Glass Wool Blanket and Glass Wool Rigid Board Insulation

Mineral Wool Insulation. Mineral wool typically refers to two types of insulation materials:

- Rock wool, a man-made material consisting of natural minerals like basalt or diabase.

- Slag wool, a man-made material from blast furnace slag (the scum that forms on the surface of molten metal).

These insulation products are commonly available as blanket (batts and rolls) and loose-fill insulation. Mineral wool materials with resin binders are also converted to slab and boards. (BEEP, Thermal Insulation of Buildings for Energy Efficiency)

Mineral Wool Blanket and Mineral Wool Loose-Fill Insulation

Polystyrene Insulation. Polystyrene is a colourless and transparent thermoplastic material and is commonly used to make foam board or bead board insulation. It is also procured as a type of loose-fill insulation consisting of small beads of polystyrene. Moulded expanded polystyrene (MEPS), commonly used for foam board insulation, is available as small foam beads. These beads can be used as a pouring insulation for concrete blocks or other hollow wall cavities, and they are extremely lightweight. Other polystyrene insulation materials similar to MEPS are expanded polystyrene (EPS) and extruded polystyrene (XPS). EPS and XPS are both made from polystyrene. EPS is composed of small plastic beads that are fused together. XPS comprises a molten material that is pressed out of a form into sheets. EPS and XPS are most commonly used as foam board insulation. (BEEP, Thermal Insulation of Buildings for Energy Efficiency)

EPS and XPS sheet

Polyisocyanurate Insulation. Polyisocyanurate (PIR) or Poly-iso is a thermosetting type of plastic, closed-cell foam that contains in its cells a hydro-chlorofluorocarbon-free (non-HCFC) gas of low conductivity. Poly-iso or PIR insulation is available as liquid, sprayed foam, and rigid foam board. It can also be made into laminated insulation panels with a variety of facings. Over time, the R-value of polyisocyanurate insulation can drop as some of the gas escapes and air replaces it – a phenomenon that is known as thermal drift. Experimental data indicates that most thermal drift occurs within the first two years after the insulation material is manufactured; thereafter, it remains unchanged unless the foam is damaged. (BEEP, Thermal Insulation of Buildings for Energy Efficiency)

Polyisocyanurate Rigid Foam Board Insulation

Polyurethane Insulation. Polyurethane (PUR) is a foam insulation material that contains in its cells a gas of low conductivity (Figure 11). Polyurethane foam insulation is available in closed-cell and open-cell configuration. With closed-cell foam, the high-density cells are closed and filled with a gas that helps the foam to expand and fill up the spaces around it. Open-cell foam cells are not as dense and are filled with air, which gives the insulation a spongy texture. Like polyisocyanurate foam, the R-value of closed-cell polyurethane insulation can also drop over time owing to thermal drift when some of the gas with low conductivity escapes and air replaces it. Like PIR, most thermal drift occurs within the first two years after the insulation material is manufactured; thereafter, the R-value remains unchanged unless the foam is damaged. Polyurethane insulation is available as a liquid sprayed foam and rigid foam board. It can also be made into laminated insulation panels with a variety of facings. All closed-cell polyurethane foam insulation products made today are generally produced with a non-HCFC gas as the foaming agent. (BEEP, Thermal Insulation of Buildings for Energy Efficiency)

Polyurethane Sprayed Foam Insulation

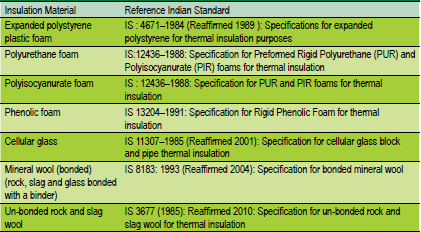

Indian Standards on Building Insulation Products. Many insulation materials and products are available in the Indian market, but may have different specifications on density and thermal conductivity values. The Bureau of Indian Standards has developed a few standards, which provide specifications of the following insulation products for buildings. (BEEP, Thermal Insulation of Buildings for Energy Efficiency)

Indian Standards on Specifications of Building Insulation Products

The insulation is much easier to install during initial construction than to retrofit later. There is a limit to how much insulation should be used. “The law of diminishing returns” says that every time you double the amount of insulation, you cut the heat loss in half. Unfortunately, the cost keeps up with the thickness of insulation, while the heat loss decreases by ever smaller amounts. (Lechner N.,2008)

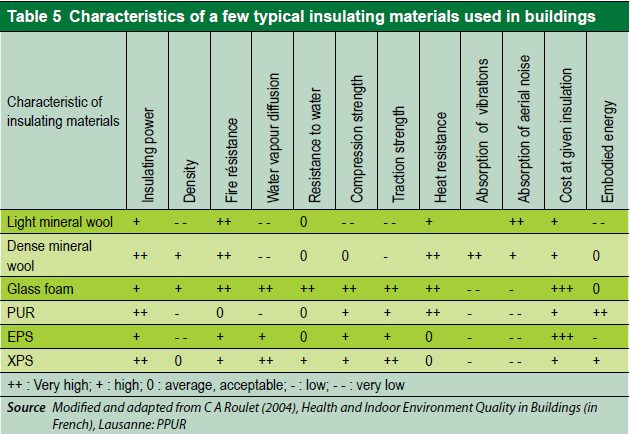

Characteristics of Insulation Materials

- Insulation should be placed on the hotter surface. In other words, for cooling during summers, insulation should be on the outer side, and in case of heating the building, insulation should be placed on the internal side.

- Insulation material should be chosen keeping in mind the following parameters – thermal performance, lifetime performance, fire safety, moisture and condensation, air infiltration and environmental benefits.

- Insulation can have a disadvantage that it can prevent the building from cooling at night.

- Insulation should be always used with a heat storing material, this storage mass should be placed inside a passively cooled building.

- In passive heating or cooling buildings, thermal insulation should be used taking into account the problem of condensation.

- When damp proof materials are used, they should always be on the warm side of the insulation.

- Use of insulation is more effective in hot climates where demand for cooling is very high.

- During summer months in hot climates, thermal insulation must be combined with an effective ventilation strategy at night (when it is cooler) to flush out the heat.

- It is recommended for architects to check with air-conditioning system designers to explore the savings provided by an insulated wall.

- Providing insulation beyond 100mm thickness does not provide additional benefit in terms of energy efficiency. Provision of the initial 25mm of insulation, provides the highest incremental energy saving. As the insulation material becomes incrementally thicker, the incremental energy saved becomes smaller and smaller until it is almost insignificant, especially after an insulation thickness of 100mm onwards. (www.nzeb.in)

In hot and humid climates, buildings need to reduce heat gain as much as possible. Insulation can help achieve this goal and it can reduce the overall requirement for AC. In warm and humid climate low thermal conductivity materials reduce the conductive heat gain.

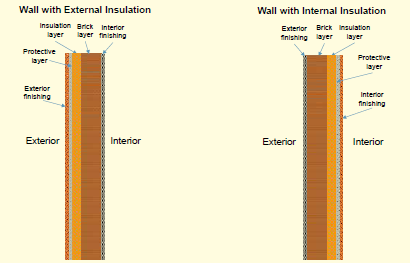

EXTERNAL INSULATION

Advantages

- Increases the time constant

- Stabilizes the temperature

- Stores excess heat or recovers stored heat

- Supresses most thermal bridges

- In cold climates, completely suppresses the risk of water vapour condensation inside the building element

Inconveniences:

- Application from outside

- Increases the time required to change the internal temperature in air-conditioned buildings located in warm and humid climate

- May increase the risk of water vapour condensation inside the building element

INTERNAL INSULATION

Advantages

- Application from inside

- Decreases the time required to change the internal temperature

- In air-conditioned buildings located in warm and humid climate

- Decreases the risk of water vapour condensation inside the building element

Inconveniences

- Thermal bridges

- In heated buildings located in cold climate, may increase the risk of water vapour condensation inside the building element

- Decreases the time constant of the building, building structure expose to the external variations

(www.beepindia.gov.in)

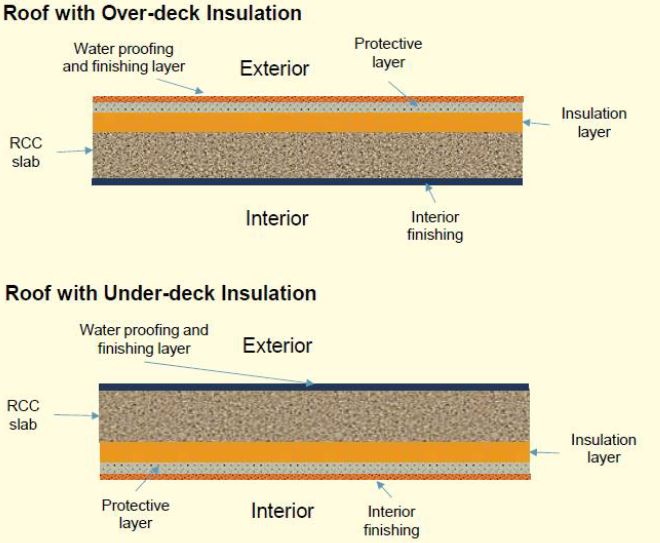

Roof Insulation

Wall Insulation

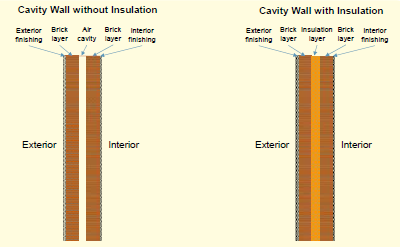

Cavity Wall Insulation

Roofs shall comply with the maximum assembly U-factors given in the tables below. The roof insulation shall be applied externally as part of the structural slab and not as a part of false ceiling.

Roof Assembly U-factor (W/m2.K) Requirements for ECBC Compliant Building

| Composite | Hot and Dry | Warm and Humid | Temperate | Cold | |

| All building types, except below | 0.33 | 0.33 | 0.33 | 0.33 | 0.28 |

| School <10 000 m2 AGA | 0.47 | 0.47 | 0.47 | 0.47 | 0.33 |

| Hospitality >10 000 m2 AGA | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 |

Roof Assembly U-factor (W/m2.K) Requirements for ECBC+ Compliant Building

| Composite | Hot and Dry | Warm and Humid | Temperate | Cold | |

| Hospitality, Healthcare Assembly | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 |

| Business Educational Shopping Complex | 0.26 | 0.26 | 0.26 | 0.26 | 0.20 |

Roof Assembly U-factor (W/m2.K) Requirements for SuperECBC Building

| Composite | Hot and Dry | Warm and Humid | Temperate | Cold | |

| All building types | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 |

Opaque above grade external walls shall comply with the maximum assembly U-factors given in the tables below.

Opaque Assembly U-factor (W/m2.K) Requirements for ECBC Compliant Building

| Composite | Hot and Dry | Warm and Humid | Temperate | Cold | |

| All building types, except below | 0.40 | 0.40 | 0.40 | 0.55 | 0.34 |

| No Star Hotel <10 000 m2 AGA | 0.63 | 0.63 | 0.63 | 0.63 | 0.40 |

| Business <10 000 m2 AGA | 0.63 | 0.63 | 0.63 | 0.63 | 0.40 |

| School <10 000 m2 AGA | 0.85 | 0.85 | 0.85 | 1.00 | 0.40 |

Opaque Assembly U-factor (W/m2.K) Requirements for ECBC+ Compliant Building

| Composite | Hot and Dry | Warm and Humid | Temperate | Cold | |

| All building types, except below | 0.34 | 0.34 | 0.34 | 0.55 | 0.22 |

| No Star Hotel <10 000 m2 AGA | 0.44 | 0.44 | 0.44 | 0.44 | 0.34 |

| Business <10 000 m2 AGA | 0.44 | 0.44 | 0.44 | 0.55 | 0.34 |

| School <10 000 m2 AGA | 0.63 | 0.63 | 0.63 | 0.75 | 0.44 |

Opaque Assembly U-factor (W/m2.K) Requirements for SuperECBC Building

| Composite | Hot and Dry | Warm and Humid | Temperate | Cold | |

| All building types | 0.22 | 0.22 | 0.22 | 0.22 | 0.22 |

More Comfortable & Healthy Interiors

Insulation reduces the heat ingress or heat loss through the walls and roofs. This results in better radiant temperatures and higher comfort in the adjoining spaces. Insulation also maintains controlled temperatures for longer periods, and provides fungus-free and microbe-free healthier environment; due to the absence of cold walls.

Lower Energy Bills

Insulating the roof and walls of a building could reduce the heating or cooling loads by 5-8% and could lead to up to 10% reduction in annual heating or cooling energy use. These savings are averaged for typical commercial buildings, and even higher savings can result in buildings with lower temperature setpoints and longer hours of air-conditioning.

As more insulation is used, the mechanical heating and cooling systems get smaller and less expensive. In many climates, superinsulation can eliminate the heating system altogether, and in some climates, it also eliminates the cooling system. Thus, large amounts of insulation can be less expensive than small amounts even for the initial cost

Sources: www.nzeb.in, www.beepindia.gov.in, Lechner N., 2008

Publications

BEE (Bureau of Energy Efficiency), “Thermal Insulation of Buildings for Energy Efficiency”,2016.

Berge Bjorn, “The Ecology of building materials”, 2009.

Lechner Norbert, “Heating, cooling, lighting. Sustainable design methods for architects”, 3rd edition, 2008.

Online Resources

Tools

Assembly U-Factor Calculator: The Centre for Advanced Research in Building Science and Energy (CARBSE) at CEPT University has developed this Assembly U-factor calculator tool. The project has been co-funded by Ministry of New and Renewable Energy (MNRE), Government of India and Shakti Sustainable Energy Foundation (SSEF)

| Manufacturer | Product | Contact |

| E-Pack Polymers Pvt. Ltd. | Rockwool insulated panel, Rockwool sandwich panel, Polyurethane panel | 2584, Rohatagi Mansion, Hamilton Road, Kashmere Gate, Delhi, Delhi, 110006, Mobile: +917210114703 Website: http://www.buildprefab.in/ |

| Kavita Trading Co. | PUF slabs, Fibre glass wool, Rock wool, Extruded Polystyrene, Ceramic wool, Polyurethane foam | 319/8, 1st floor, pantnagar Sidhivinayak Co Hsg sct., Hingwala Lane, near popular hotel, pantnagar, Ghatkopar(E), Mumbai, Maharashtra, 400075, India Website: http://www.kavitatrading.net/ |

| Nataraj Insulation | Resin bonded insulation slabs, Rockwool slabs | 303, Shyam Samip, 35, Urmi Society, BPC Road, Nr. Haveli, Vadodara, Gujarat, 390007, India Mobile: +919206074260 Website: http://www.jacketinsulation.com/ |

| Polybond Insulation PVT. LTD. | Loose Mineral wool, Rockwool building rolls, LRB Rockwool Mattress | Plot No-56, A/17, Nehru Nagar West, Bhilai, Chhattisgarh, 490020, India Mobile: +917533008954 Website: http://polybond.co.in |