Vitals

-

- Owner

- Kiran Chavan

-

- Location

- Nashik

-

- Building Type

- Office

-

- Operating Hours

- 8.5 hrs/day

-

- Total Floor Area Unit

- SQ. M.

-

- Total Floor Area

- 260

-

- EUI/EPI

- 26.5 KWh/sqm/year

-

- Building Name

- Green Space Realtors

Project Team

-

- HVAC Engineer

- Surendra Shah (Structure Cooling)

-

- Green Building Consultant

- VK:environmental LLP

-

- Architect

- Sanjay Patil

Building Design

-

- Orientation

- North-South

-

- Window

- Windows are well shaded and have an equivalent SHGC of 0.66

-

- Wall

- Climate Responsive wall envelope designed to cut down heat gains and maximizing daylight. Use of double wall in the building envelope made of fly ash bricks and brick cladding with air gap

-

- Roof

- Use of high albedo reflective paint with SRI>0.5 to reduce heat gain from roof

-

- WWR

- Window-to-Wall ratio is 30 percent.

-

- Daylighting

Designed to have the maximum unobstructed natural light and views

Natural Daylighting

-

- Artificial Lighting System

Internal lighting using solar PV

Energy efficient lighting fixtures and equipment

-

- Passive Cooling System

Turbo ventilators to facilitate stack ventilation

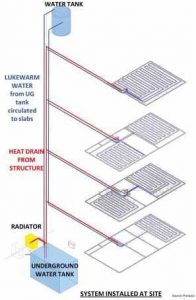

ThermOdrain system (TOD) is installed. 21 mm diameter plastic pipes laid out in a grid on the plinth of all floors.

Schematic diagram of the TOD system

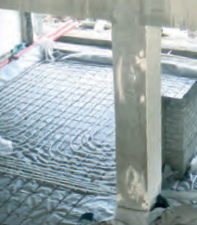

Layout of Pipes for Radiant Cooling of Floor

Layout of Pipes for Radiant Cooling on Ceiling

– The system is designed to remove 242 Btu/sq. ft./hour (763 W/m2) of heat from the plinth mass of the structure

Laying out the coil of pipes above RCC slab with screed below tiling at the time of construction of terrace

The water picks up the roof heat (water absorbs 4,100 joules per litre per Deg. C) and passes through a radiator that rejects

most of it. Lukewarm water is stored in the tank and recycled through the radiator at night, when the cool night air absorbs the

residual heat. The cycle starts again the next morning. Energy for the pmp and the fan is supplied by the solar PV system.

-

- Datasets/Measurement

Assessment of ThermOdrain system:

The ThermODrain system was validated through empirical assessment by recording hourly surface temperature of top and bottom of the terrace slab – with and without high albedo paint. Measurements were made in peak summer (May 2017) using calibrated data logger and thermocouple sensors; hourly indoor air temperature/dry bulb temperature (DBT) and relative humidity (RH) were measured using Ebro temperature and humidity logger; hourly globe temperature was manually recorded using JRN 76 mm

black globe thermometer. Monthly electricity bills were obtained from the office to determine the Energy Performance Index (EPI) and compared with prevailing benchmarks provided by the Bureau of Energy Efficiency.

-

- Form

- The building shell has been designed based on the sun path, shadow patterns, wind directions, rainfall and humidity levels

-

- Shading

Building Performance

-

- Space Conditioning

TOD system provides thermal comfort indoors in peak summer without the use of mechanical air conditioning system. The system prevents the solar heat re-radiation from roof and floors by absorbing it before it adds to the sensible heat load of the building and

cause thermal discomfort to the occupants.

Finances

-

- Operational Cost Savings

In terms of capital cost, the structural cooling system is 50 percent less costly than a conventional HVAC system and the recurring energy cost is a mere 8.7 percent of a conventional system. The total life cycle costing (capital and running cost) of the TOD system for a period of 10 years amounts to Rs. 6/ sq. ft./ year (US $1 per sq. m) as compared to Rs. 30/sq. ft./year for a conventional HVAC system.

The system is passive except for 3 elements – Pump for the pipes grid, Fan for Radiator and Pump for Overhead Tank. The total energy consumption of these amount to 3,000 kwh/year as compared to 34,560 kwh/year required for 12 TR of conventional HVAC system (at 1.2 kw/tonne of refrigeration and set temperature of 24-degree C) required for the building. The difference in energy consumption is more than 10 times. The active components of the system are supplied energy primarily from solar PV panels.